Baling presses with folding hoppers

Baling presses with folding hoppers

- Effective processing of scrap from pressing shops

- Dosing equipment with scrap weighing device

- Environmentally friendly

- High operational output

| CPS 160 | CPS 320 | CPS 630 | |

|---|---|---|---|

| Pressing force: the last operation (repressing) (t) | 160 | 330 | 630 |

| Bale (Height × Width) (mm) | 300 × 300 | 400 × 400 | 600 × 600 |

| Charging chamber (Length × Width × Depth) (mm) | 1480 × 900 × 750 | 1650 × 1400 × 1250 | 5000 × 1960 × 1600 |

| Max. thickness of steel scrap (mm) | 4 | 6 | 8 |

| Max. number of bales (1/hr.) | 92 | 90 | 48 |

| Max. output (steel scrap) (t/hr.) | 12,5 | 28 | 55 |

| Power input installed of main pumps (kW) | 75 | 2 × 75 | 3 × 75 |

CPS 160

- Effective processing of cut scrap from automotive factory pressing shops

- CPS 160 – Bale section: 300 x 300 mm

- CPS 320 – Bale section: 400 x 400 mm

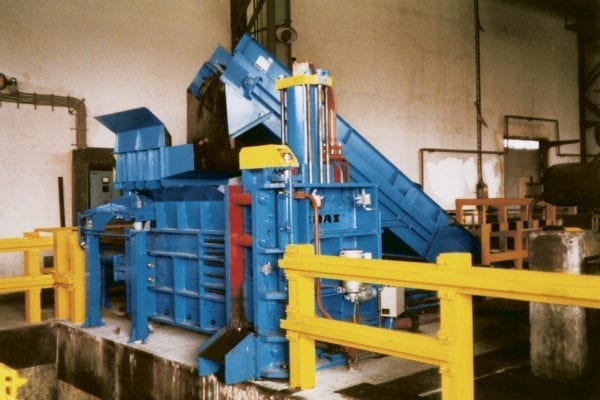

- CPS 160 baling press at the pressing plant of a car body producer

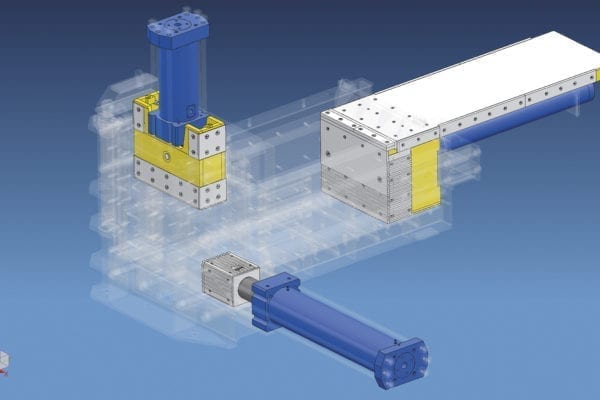

- Schematic of hydraulic parts from a CPS press

- ZDAS CPS 180 balling press in the hall

- ZDAS CPS 320 baling press in a pressing shop of a large automotive manufacturer

CPS 320

CPS 320 baling presses can be implemented into scrap processing lines of pressing shops in automotive factories. The unit includes conveyers that bring cuttings from individual pressing workplaces and enable transport of compressed bales to the warehouse or directly to the dispatching area. A working cycle of 30 seconds/bale is achieved with an average bale weight of 200 kg, provided that loading is continuous.

- CPS 320 press with a hopper

- Output of bales

- Press drive in a separate cabin

CPS 630

The CPS 630 hydraulic baling press is designed for processing amortisation scrap in scrap-processing-oriented companies. This baling press is especially suitable for processing the following: light large-volume depreciation scrap, crop ends of sheet with a thickness up to 8 mm, car bodies, parts of agricultural and transport machines, etc. To reach a high output, it is suitable to install a batching tilting hopper to ensure a continuous feed of scrap and discharge of final bales.

Features of the press:

- The three-stage pressing concept guarantees high compactness of bales

- Replaceable abrasion-resistant lining of working surfaces of the press

- Knives of the charging hopper enable cut off of protruding scrap

- The drive is a compact assembly group

- Simple operation by remote control

- The drive is provided with an environmentally-friendly oil tray