CNS 400 K

CNS 400 K

MOBILE CONTAINER SCRAP SHEARS

- Appropriate for cutting mixed scrap

- Up to 12 tons of processed scrap per hour

- Continuous loading during the cutting cycle

- Diesel or electric engines

- Easy to transport, simple to operate

- Original engineered solution

- Highly stressed parts are made of castings

- More than 200 machines in operation

- Highly reliable with an extended service life

- ZDAS’s mobile shears comply with emission limits

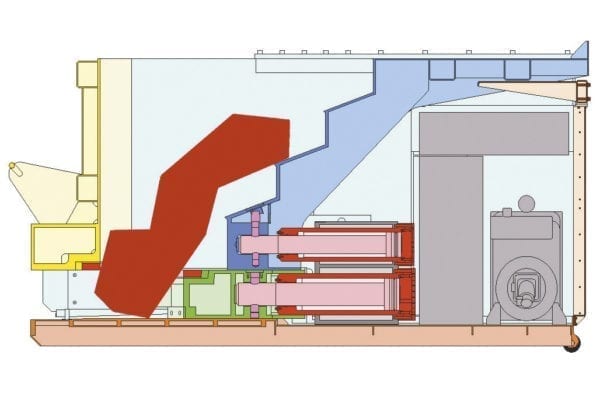

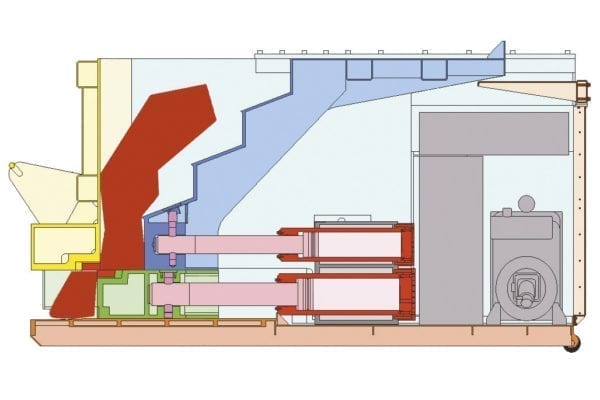

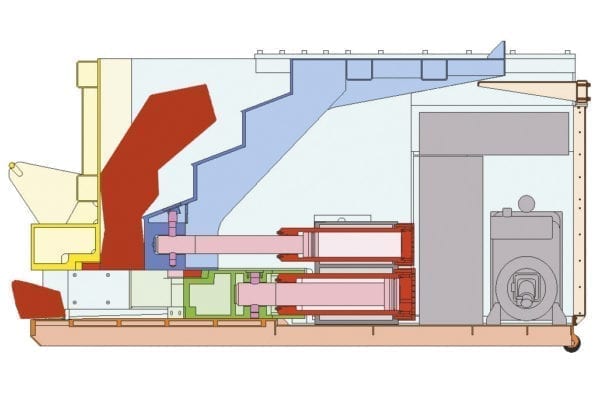

Shears workflow

Scrap is filled into the hopper by means of a grab loader. Due to the horizontal movement of the holder and the scrap’s dead weight, it falls to the bottom of the loading chamber and into the cutting space. After having been compressed on the front wall, the scrap is cut by the horizontally-moving tool-holding slide via the blades on the front wall. While the tool-holding slide is moving horizontally, the processed material is pushed out via the blades on the container’s front wall. While returning to the rear position, the loaded scrap moves under its own weight into the shears’ interior.

- Container shears mode of operation

- Protracting of the tool-holding slide (shearing scrap)

- Retracting of the tool-holding slide

Basic technical parameters of the CNS 400 K shears

| CNS 400 K | CNS 400 K-E | |

|---|---|---|

| Drive | Diesel | Electric |

| Outer dimensions (L x W x H) (mm) | 5 330 × 2 500 × 2 700 | 5 330 × 2 500 × 2 700 |

| Processing (steel scrap) (t/hod.) | 7-12 | 7-12 |

| Cutting force (t) | 400 | 400 |

| Max. cutting section (with tensile strength of 440 MPa) | ||

| – Diameter (mm) | 110 | 110 |

| – Square (mm) | 90 × 90 | 90 × 90 |

| Engine output (kW) | 110 | 75* |

* Při napětí 400 V a frekvenci 50 Hz

- The CNS 400 K shears on a hooklift trailer

- Loading the container shears on a carrier

- Layout of the workplace with the CNS 400 K shears

- Loading the CNS 400 K shears with long scrap

- Processing scrap

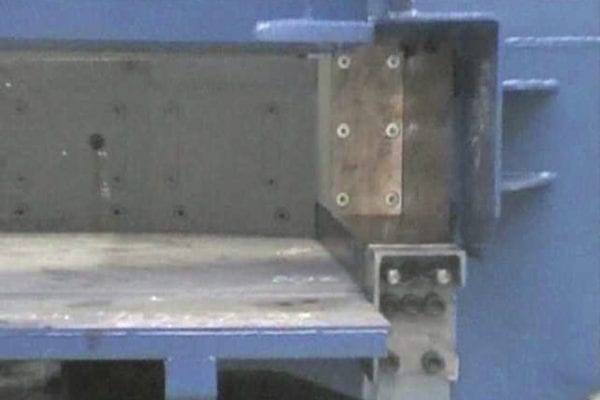

Compared to standard stationary shears, ZDAS container shears offer an original method of cutting by means of a horizontal movable tool-holding slide. This slide is located on the lower part of the loading chamber.

The shears can be remotely operated.

Like standard large-volume containers, these shears can also be lifted and moved by a hooklift truck.

The shears can be delivered with both diesel and electric engines. In addition to the standard version, Tropic and Arctic variants are also available.

The CNS 400 K shears are offered with the following options:

- Top hopper

- Guide for loading long pieces – internal hopper

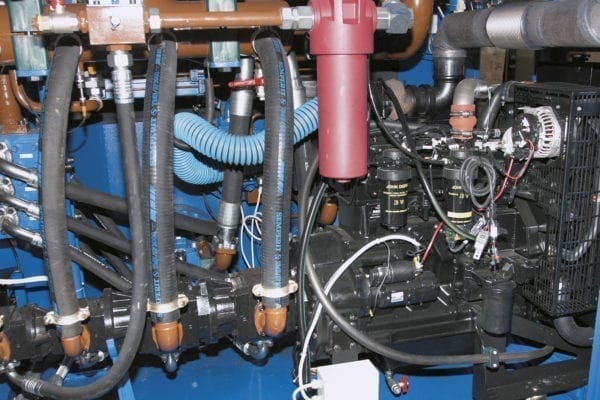

CNS 400 K – diesel

- Due to the effective diesel-hydraulic power pack, low consumption is achieved – as low as 1.2 l per one ton of scrap (depending on the type of scrap)

- A control system from reputable suppliers, which displays error messages, is installed in the machine’s distribution box

- Hydraulic components with extended service lives are supplied by well-respected global manufacturers

- The standard water-cooled diesel engine guarantees trouble-free operation even at extreme temperatures of –20 °C to 35 °C

CNS 400 K-E – elektro

- For scrap yards with access to electricity, ZDAS offers a variant of the shears with an electric engine

- Control system including error messages is installed inside the machine’s distribution box and is supplied by well-respected manufacturers

- Lower costs for one ton of processed scrap

- Quiet operation

- Minimum amount of engine maintenance

- Longer service life of the pumps when working at lower speeds

- Maintenance downtime is reduced

Both diesel and electric versions can be supplied in Tropic (up to +45°C) or Arctic (up to –30 °C) variants

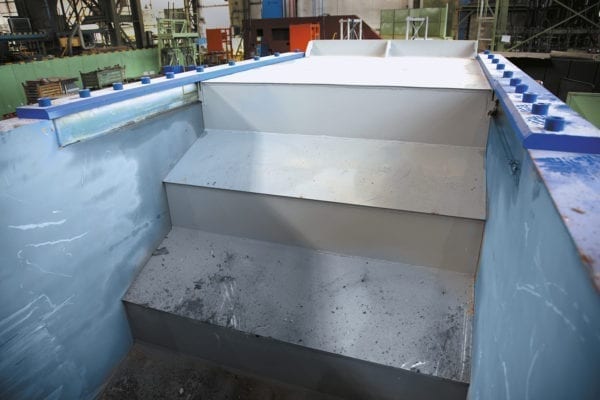

- View of the cutting blades, which are the full width of the loading chamber

- View of the scrap holding space

- Accurate guiding of the tool-holding slide ensures transmission of maximum cutting force to the scrap

- Remote control of the shears ensures safe operation and control by one operator