CNS 730/190

CNS 730/190

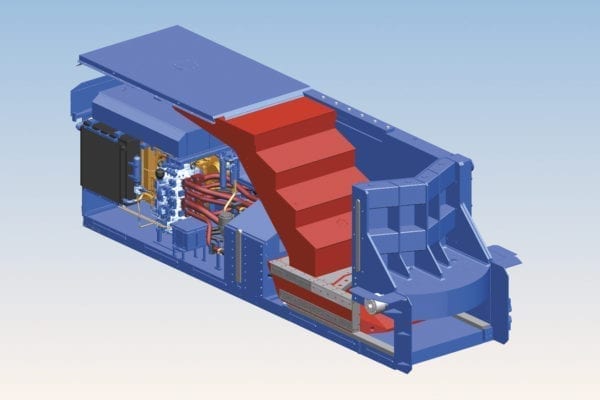

SEMI – MOBILE SCRAP SHEARS

- Suitable for cutting heavier and larger pieces of scrap

- High performance – up to 20 tons of processed scrap per hour

- Diesel or electric engines

- Extremely stressed parts are made of castings

As a result of the overwhelming success of ZDAS standard container shears, amore powerful series having 730 metric tons of cutting force was developed. The hori zontal tool-holding slide cutting techni que was kept and the framework was reinfor ced appro priately. In order to maintain the high performance of the shears, a higher output hydraulic drive was installed. The top hopper enables filling of the load space with bulky or long scrap. With respect to their robust construction and force, the CNS 730/190 shears are fully comparable to the stationary shears

from their competitors. The difference is that they can be easily moved using a flatbed trailer. The shears can be loaded on a flatbed using their own hydraulic lifting legs and/or they can be loaded by crane. Within several minutes they are ready for transport to another scrap yard.

| CNS 730/190 MTC | CNS 730/190 E | |

|---|---|---|

| Drive | Diesel | Electric |

| Outer dimensions (L x W x H) (mm) | 7 950 × 2 500 × 2 700 | 8 300 × 2 500 × 2 700 |

| Processing (steel scrap) (t/hod.) | 12-20 | 12-20 |

| Cutting force (t) | 730 | 730 |

| Max. cutting section (with material strength of 440 MPa) | ||

| – diameter (mm) | 160 | 160 |

| – square (mm) | 140 × 140 | 140 × 140 |

| Engine output (kW) | 205 | 2 × 75* |

* At 400 V / 50 Hz

- Loading scrap into the CNS 730/190 shears

- View of the cutting area

- Examples of heavy scrap processing

- Examples of heavy scrap processing

The CNS 730/190 shears are offered with the following options:

- Top hopper

- Guide for loading long pieces – internal hopper

- Simple loading/unloading using the hydraulic legs

CNS 730/190 MTC – Diesel

- High performance shears with consumption as low as 2.5 l of oil per one ton of processed scrap

- Control systems from reputable suppliers are used

- A pusher with 190 tons of force enables the scrap to be pre-compacted

- A combination of pumps eliminates hydraulic shocks and the water-cooled diesel engine is reliable even at extreme temperatures of –20 °C to +35 °C

CNS 730/190 E – Electric

- ZDAS offers an optional electric engine for local scrap yards in industrial or suburban areas with access to electricity

- Lower costs for one ton of processed scrap

- Quiet and ecological operation

- Low maintenance on the engine

- Longer service life of the pumps when working at lower speeds

- Simple maintenance and operation

Further advantages:

- Continuous loading of scrap into the hopper while pushing out the processed scrap

- High-capacity oil tank enables as much as 16 hours of continuous operation

- No foundation is needed to install the shears – all you need is an even and firm surface

- Remote control of the shears by the scrap yard operator

- Control system Remote control of the shears by the scrap yard operator panel with screen